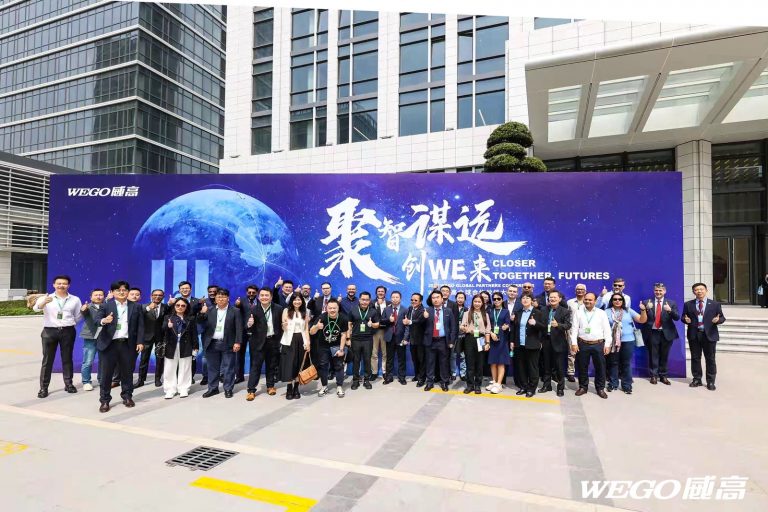

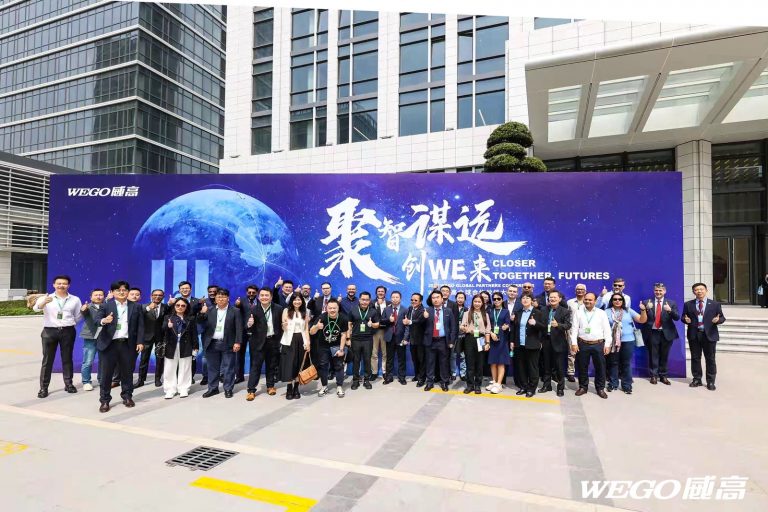

On April 10, 2025, WEGO successfully held its 2025 Global Partner Conference in Shanghai, bringing together representatives from over 100 medical companies across more than

Safe, efficient, experienced, advanced technology, professional.

WEGO

Cranial Cervical Stabilization System is designed to provide reliable support and stability for patients with cervical spinal issues. Built upon years of expertise and innovation, this system offers advanced solutions for surgeons tackling complex cervical spine disorders.

WEGO Medical’s Cranial Cervical Stabilization System is designed to provide reliable support and stability for patients with cervical spinal issues. Built upon years of expertise and innovation, this system offers advanced solutions for surgeons tackling complex cervical spine disorders.

With a focus on safety, efficiency, and precision, WEGO Medical’s Cranial Cervical Stabilization System empowers surgeons to effectively address the challenges of cervical spine stabilization, ensuring optimal patient outcomes.

| Product Material |

|

| Ball Socket Structure |

|

| 3-point cranial fixation |

|

| Raw material |

|

| Processing technic |

|

| Advanced testing equipment and strict testing methods |

|

On April 10, 2025, WEGO successfully held its 2025 Global Partner Conference in Shanghai, bringing together representatives from over 100 medical companies across more than

Oxygenators are medical devices used for life-support surgeries such as cardiopulmonary surgery and extracorporeal membrane oxygenation. It can act as an artificial lung for gas exchange,

Whether it is for vaccinations, drug injections, or complex clinical treatments, syringes are indispensable tools. As medical technology and patient needs improve, it is critical

Extracorporeal circulation is a life support technology that uses tubes to connect various devices, such as oxygenators, to drain venous blood outside the body. After